X-CUP™ Sustainability

How We Made X-CUP™ Consumer & Planet Friendly

As an industry leader in plastic manufacturing, we are deeply committed to developing a sustainable single-serve cup solution. One that seamlessly integrates with current operations while promoting consumer-friendly recycling practices.

RECYCLABLE MATERIALS

Saving Billions of Single-Serve Cups From Landfills

We created a recyclable* coffee pod that can help reduce waste and the resources used to transport scrap to landfills.

Research shows that 75% of US consumers are concerned about the environmental impact of the products they buy.

In a society that has embraced eco-friendly practices, it’s important to stay relevant and change your operations to honor what your consumers care about most.

*Please confirm locally the recyclability of this component; not all communities accommodate coffee pod recycling

X-CUP™ SUSTAINABILITY FACTS

Protect Your Roasts & Reduce Waste

- Recyclable materials*

- Can be made with up to 25% post-consumer waste material

- Promotes consumer-friendly, responsible recycling

- As single-serve system, less impactful environmentally than drip-brewing methods

*Please confirm locally the recyclability of this component; not all communities accommodate coffee pod recycling

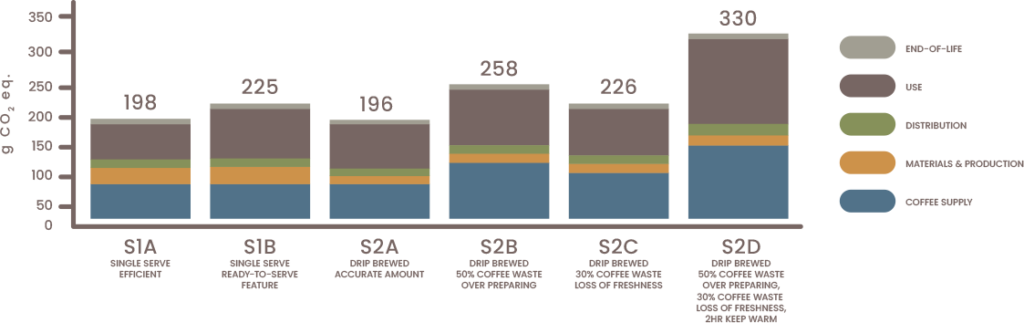

Life Cycle Comparison

Coffee waste and energy consumption can vary greatly between coffee brewing systems in terms of net environmental impact. Single-serve methods, for instance, generally create less impact when compared to the actual consumer habits of drip-brew systems.

THE X-CUP™ ECOSYSTEM

Creating Sustainable Solutions

We welcome the opportunity to partner with customers to develop a seamless X-CUP recycling system. Together, we can implement an efficient bag return program, ensuring that X-CUP coffee pods are recycled* after use.

Today’s MRF (materials recycling facility) remains unequipped to process most of the coffee pods on the market. Together we can create an X-CUP’s ecosystem that provides the answer.

- Consumer-friendly return bags provided for used pods.

- Every used pod component can be recycled or repurposed.

- Coffee grounds converted into fertilizer.

- Promotes responsible recycling.

*Please confirm locally the recyclability of this component; not all communities accommodate coffee pod recycling